Weepers, Efflorescence, and other Concrete Pool Shell Problems

Believe it or not, swimming pools can leak in both directions. Most of us think of pool leaks as water escaping out of the pool, but this article is about water pushing into the pool from the outside from hydrostatic pressure. We'll discuss what the consequences are, how to fix them, and more importantly, how to prevent these issues from the beginning.

The concrete pool shell

Rebar and plumbing are installed, and soon there will be wooden concrete forms to shoot shotcrete against to make this swimming pool's vanishing edge wall. Photo Credit - SSG Pools

Let's start with an overview of how pools are actually constructed. A hole is dug, plumbing is installed for all return lines, the main drain, skimmer(s), etc., and then gravel and rebar are put into place before shooting concrete. Swimming pool shells are made of pneumatically applied concrete: shotcrete or gunite. They're both technically shotcrete, but in the pool industry, the difference between shotcrete and gunite is how water is mixed with the cement. Shotcrete is pre-mixed, wet concrete that is pumped through a hose, whereas Gunite is a dry mix pumped through the hose that is met with water at the end. A gunite pool shell is harder to shoot, as it takes a more skilled team and nozzleman.

Most pool builders prefer wet mix, but there are some very good pool builders who prefer gunite, and they have valid reasons. While some builders say shotcrete is better for shooting pool walls, builders like Dana Anderson of Anderson Poolworks prefers pre-mixed (wet) shotcrete. He told us:

"My perception is that ready-mix shotcrete is more consistent and ‘safe’ as mix designs including admixtures are controlled by a calibrated plant process instead of by field-employees as with ‘dry-mix’ shotcrete [gunite]." - Dana Anderson, Anderson Poolworks

As long as the minimum of 4000 PSI is met, per industry standards, gunite and shotcrete both work for pool shells. According to Paolo Benedetti of Aquatic Technology, if you don't shoot a pool shell with at least 4000 PSI, it will be too porous and weak, even when using penetrating sprays like colloidal silicate. Those products will not work well on a 2500 PSI shotcrete, for example.

To be clear, no concrete is waterproof to begin with. And it's not designed to be.

Water's role in concrete curing

Much like plaster surfaces, concrete is made up of aggregates and cement. Cement must hydrate and cure, which involves chemical reactions happening within the mix itself as it hardens. Water is essential for concrete to cure. According to Curt Straub, a concrete expert and pool builder:

"The simple fact is that if you don't cure the shell, moisture exits the concrete too quickly, making the material lose mass and shrink. The result is unsightly cracks in the plaster finish, and this is not "just something that concrete does." It is, in fact, entirely the result of skipping a key step in the application process. And the sad thing is that curing involves nothing more than keeping the shell moist for a few days. That's all there is to it." - Curt Straub, "Finding the Cure"

The pool builders and concrete experts we spoke to agreed that proper curing is an essential part of a good pool. Rushing the cure time of a concrete pool shell is almost guaranteeing costly mistakes and warranty issues down the road. According to Reid Schindler, a high-end pool builder in Oklahoma:

"So many concrete problems can occur when you don't give shotcrete enough water and enough time to cure properly. I spray on colloidal silicate within 24 hours–usually the same afternoon, because we schedule our shotcrete to be done early in the morning–and then set up a watering system to keep the shell wet. If you don't give the concrete the water it needs, it will find water anywhere else it can, which means the soil on the back side of the pool shell. This leads to efflorescence and mineral deposits, cracks, and other costly problems. Rushing a project means concrete has not had enough time to reach its final state." - Reid Schindler, CBP

Keeping the concrete wet for at least 7 days is one of many best-known practices for concrete in general–not just for swimming pool construction. Think of shotcrete needing water sort of like the pool water needing LSI balance. If the water doesn't have enough calcium carbonate in saturation, water will seek it wherever it is available, which usually means the plaster. Concrete will do the same thing when seeking moisture. You can either give it the water it needs, or it will find it in the soil around the pool, which leads to problems.

Keeping the concrete wet for at least 7 days is one of many best-known practices for concrete in general–not just for swimming pool construction. Think of shotcrete needing water sort of like the pool water needing LSI balance. If the water doesn't have enough calcium carbonate in saturation, water will seek it wherever it is available, which usually means the plaster. Concrete will do the same thing when seeking moisture. You can either give it the water it needs, or it will find it in the soil around the pool, which leads to problems.

Related: Protect Plaster with an LSI-Balanced Startup

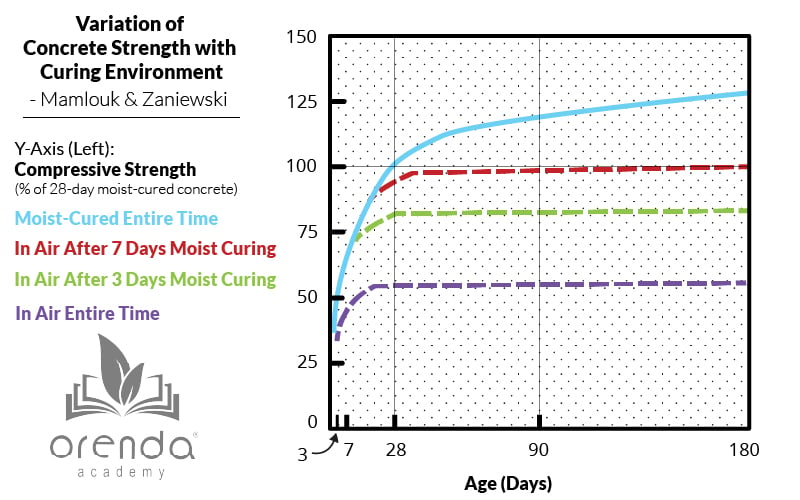

Below is a chart we re-created, which originally comes from a textbook by Mamlouk and Zaniewski. We recreated it only because the original was hard to read. Anyway, the chart shows concrete curing strength percentage based on moisture levels over time. Properly hydrated concrete can reach 100% strength at 28 days, but look at what happens if it is not kept wet. It now makes a lot more sense why good pool builders keep their pool shells wet for a minimum of 7 days.

Source: Materials for Civil and Construction Engineers - Mamlouk & Zaniewski

Cold Joints and Shrinkage Cracks

Both Dave Peterson and Paolo Benedetti brought up cold joints in their conversations with us, which was fascinating because we had never even heard the term before. According to Dave:

"A cold joint occurs when you have concrete that has already cured or partially cured, and then you add more concrete to it. There's basically a crack or a weakness between the two concrete sections that can sheer apart when the new concrete cures. It's a weak spot in concrete, so if you ever see efflorescence or weepers in a straight line, it's usually because there is a cold joint there." - Dave Peterson, P.E.

Paolo expanded on that:

"Cold joints don't happen as often with shotcrete because of its high velocity. It's usually when concrete is poured or "casted" over shotcrete, like if a company pours more concrete to better form their steps after they have already shot them. You cannot cast on shot, but you can shoot on cast. This is why good pool builders generally pour or shoot the concrete floor of the pool first, then shoot the walls." - Paolo Benedetti

Then there are shrinkage cracks. While water is essential for curing, having too much water in the concrete mix itself can be problematic. According to Watershape University, there are limits to the amount of water that can be put into the concrete mix. Consider using admixtures allowing concrete to flow without using excessive water in the mix, because too much water can mean a higher water-to-cement ratio than desired, which means less dense concrete.

As mentioned in Curt Straub's quote earlier, shrinkage cracks are not "just something concrete does." They occur as a direct result of moisture leaving the concrete too fast, causing the material to lose mass too quickly, which cracks it apart from its surrounding material. Cracks can lead to leaks and possibly weepers. When the concrete pool shell has shrinkage cracks, simply layering waterproofing or other membranes over the shotcrete does not necessarily stop the problem. In fact, extra layers can lead to delamination, and the plaster finish applied over all of it can eventually have cracks too. That opens the door to moisture being trapped behind the plaster, which can eventually ooze out and cause calcium nodules.

As mentioned in Curt Straub's quote earlier, shrinkage cracks are not "just something concrete does." They occur as a direct result of moisture leaving the concrete too fast, causing the material to lose mass too quickly, which cracks it apart from its surrounding material. Cracks can lead to leaks and possibly weepers. When the concrete pool shell has shrinkage cracks, simply layering waterproofing or other membranes over the shotcrete does not necessarily stop the problem. In fact, extra layers can lead to delamination, and the plaster finish applied over all of it can eventually have cracks too. That opens the door to moisture being trapped behind the plaster, which can eventually ooze out and cause calcium nodules.

With enough hydrostatic pressure, weepers can cause delamination, shown on the left. On the right, a common place for weepers is a transition zone, such as a plumbing inlet. Neither of these problems are water chemistry related, nor are they a plaster failure. They are a direct consequence of a weak concrete pool shell, and a lack of sufficient waterproofing.

With enough hydrostatic pressure, weepers can cause delamination, shown on the left. On the right, a common place for weepers is a transition zone, such as a plumbing inlet. Neither of these problems are water chemistry related, nor are they a plaster failure. They are a direct consequence of a weak concrete pool shell, and a lack of sufficient waterproofing.

Consequences of a weak concrete pool shell

Failure to properly install or hydrate a concrete pool shell can lead to water permeability issues. Specifically let's focus on water coming into the pool from the outside of the shell from hydrostatic pressure. There are two main consequences.

Efflorescence

Efflorescence occurs when water seeps through concrete and excretes mineral deposits–usually calcium carbonate–on the other side. It can be seen coming in through the concrete pool shell when the concrete is forced to draw water from the soil around the pool. Once the pool is built, however, the most common places to see efflorescence are on the outside of raised spas and spillovers (like vanishing edge walls), because there is hydrostatic pressure that pushes water through the concrete wall to the outside.

Efflorescence occurs when water seeps through concrete and excretes mineral deposits–usually calcium carbonate–on the other side. It can be seen coming in through the concrete pool shell when the concrete is forced to draw water from the soil around the pool. Once the pool is built, however, the most common places to see efflorescence are on the outside of raised spas and spillovers (like vanishing edge walls), because there is hydrostatic pressure that pushes water through the concrete wall to the outside.

Efflorescence can occur even without cracks or cold joints. But if those structural weaknesses are present, water follows the path of least resistance.

We are often asked about efflorescence at Orenda, because it is very often confused with carbonate scale. While efflorescence is usually calcium carbonate, it is not caused by a high-LSI violation. It is actually a symptom of a failure to effectively waterproof. We know this because the pool cannot deposit scale in a place where water does not soak. We may devote an entire article in the future to efflorescence, because it is a huge problem for swimming pools around the country, and can occur even with perfectly balanced water chemistry.

Weepers

In the photo above, the white spots are efflorescence, and the wet spots are weepers. No type of plaster finish can hold this pressure back, and it is guaranteed to fail at some point.

Weepers are basically water leaks that penetrate through concrete. Unlike efflorescence, weepers are usually a result of flawed workmanship when shooting the concrete shell. A tell-tale sign of weepers is wet spots, which means water is still flowing...whereas efflorescence shows mineral deposits that are not necessarily wet.

It is not uncommon to find multiple problems with a weak concrete pool shell. Weepers (wet), nodules (white calcium 'blisters' oozing down), cracks and delamination. Again, these issues are unrelated to water chemistry. This concrete shell needs to be reinforced, if not re-shot entirely.

We spoke with several experienced pool builders and shotcrete experts, and they agreed that weepers can be prevented by proper shotcrete application. That means a sufficient pressure (PSI), thickness, rebar structure, and–perhaps most importantly–consistent material. Consistent material means discarding "rebound" waste and not troweling it back into the concrete itself. Rebound is shotcrete aggregate that bounces off the pool wall and lands on the floor. It is now weaker material that should not be blended back into the pool shell, because it will compromise the integrity of the wall. According to Robert Guarino, owner of South Shore Gunite Pools:

"Weepers come from improperly applied material. A common weeper spot is jack stand holes. They are hand packed and should be shot in the same way as the other work. Steps are another cause of weepers. Many companies use shavings and rebound to make the steps. When it rains or it is hosed down, the rebound and shavings hold the water and when drained, it “weeps” out. Again, poor application." - Robert E. Guarino, SSG Pools

If there is enough hydrostatic pressure behind the shell, water can push through any crack. In other words, water needs a concrete flaw that it can flow through to be considered a weeper. According to waterproofing expert Vito Mariano:

"No matter where the moisture comes from, concrete will always absorb water like a sponge. If there are structural flaws like cracks or voids, water with enough hydrostatic pressure can push all the way through, and that's called a weeper." - Vito Mariano, Basecrete USA

How to fix concrete permeability problems

Efflorescence and weepers have to do with the quality of the concrete pool shell and how it was applied. Fixing each one is different. For efflorescence, it takes proper waterproofing, ideally on both sides of the concrete (in the case of a raised spa or vanishing edge wall). If it is occurring after the pool is full, this may require a new waterproofing layer and bond coat before resurfacing the pool, or replacing tile, stone, etc.. It's messy, and until the moisture issue is addressed, efflorescence will keep coming back. That's right, there are no chemical solutions to efflorescence (gasp, not even SC-1000). Sure, chemicals can clean off the calcium, but it will come back until the water source is blocked.

In other words, to fix an efflorescence problem, chip off the surfaces (which removes the visible efflorescence), and waterproof before resurfacing. The efflorescence cannot come back if it's properly waterproofed.

Shrinkage cracks and cold joints cannot easily be fixed after they are formed, which is why proper concrete curing with adequate water is so paramount. There are products to help seal the concrete and reinforce it, such as colloidal silica and other admixtures. We are not experts on these products, but there are several manufacturers in the swimming pool business that can better answer your questions. Vito said there are caulks and epoxy products that can be used, but it's not ideal.

Of all the experts we spoke to for this article, most agreed the best way to handle weepers is to chip out (or cut out) the damaged areas and re-shoot it with shotcrete the right way. Another alternative for small, isolated weepers, according to Vito Mariano:

Either way, to fix a weeper, plaster finishes will have to be chipped out and replaced; at least in that area."You can chip out around the weeper, and take dry, unmixed hydraulic cement and pack it into the void where the water intrudes. This water will absorb the moisture, and when it stops absorbing the moisture, you can apply an anti-fracture mesh membrane over the affected area, and waterproof over that." - Vito Mariano, Basecrete USA

How to prevent concrete pool shell issues

As you probably already know, Orenda is about proactive pool care. So how about proactive concrete care? To prevent weepers and the other issues, shotcrete/gunite needs to be applied properly, which means no rebound material being blended back into the walls or steps, and follow industry standards for compaction, PSI and water-to-cement ratio.

Waterproofing

In our opinion, after shooting the pool shell, a best practice and relatively-cheap insurance policy is to spray on colloidal silica within 24 hours as an initial waterproofing step. While this may not be entirely necessary for all of the shell, it is absolutely necessary for raised spas, vanishing edge walls, tile lines, and any other concrete that holds water back from open air. As a best practice, why not spray it on the entire concrete pool shell?

For a minimum of the first seven days, every source we found said that shotcrete needs water to properly cure. So keep the concrete wet! We love the drip system idea that Reid showed us, and some others use lawn sprinklers on a timer. you can be creative, just make sure the concrete has adequate water every day so it has no reason to pull moisture from the earth behind the pool wall.

After colloidal silica, according to Garrett Sancomb, an experienced waterproofing rep and pool builder we spoke with, an secondary waterproofing membrane layer completes the system (TCNA standard P602). As mentioned before, we are not experts on waterproofing products, so consult the manufacturers for instructions on how to apply them (and what the proper sequence is!).

Transition areas

Transition areas are the most at-risk areas for leaks in either directions. They include lights, fittings, penetrations, etc. Anywhere that two different types of materials touch. To waterproof these areas, use a poly-sulfate waterproofing caulk or epoxy, then pack the area with hydraulic cement, and waterproof over it with the rest of the shell. You can use an anti-fracturing mesh around these zones in the process too. But of course, the best way is to shoot the shotcrete properly in the first place.

Transition areas are the most at-risk areas for leaks in either directions. They include lights, fittings, penetrations, etc. Anywhere that two different types of materials touch. To waterproof these areas, use a poly-sulfate waterproofing caulk or epoxy, then pack the area with hydraulic cement, and waterproof over it with the rest of the shell. You can use an anti-fracturing mesh around these zones in the process too. But of course, the best way is to shoot the shotcrete properly in the first place.

If you do these things, the likelihood of you having water permeability issues is significantly reduced. If you don't think these best practices are worth the extra time, effort and money, consider how much a warranty claim costs you instead. The pool owner deserves a structurally sound swimming pool that they paid for, and they are depending on the pool builder (and of course, all their sub-contractors) to deliver it. That means the quality and integrity of the concrete pool shell is the responsibility of the pool builder; not the homeowner.

Final Thought

The integrity of a concrete pool shell is critical. So take no shortcuts. Shoot the concrete correctly, remove the rebound, hydrate it properly so it cures, then waterproof as necessary. Doing these steps will prevent all the issues mentioned in this article. If you already have these problems on your pool, feel free to contact us and perhaps we can point you in the right direction and/or refer you to people who can help.