Understanding Fiberglass Pools

Of the three most common types of in-ground swimming pools (concrete, vinyl liner, and fiberglass), fiberglass pools are sold as having the least maintenance and risk of problems. For the most part, that's true. But as we will learn in this article, water chemistry still matters in fiberglass pools. Especially calcium hardness and overall LSI balance.

Note: There are several reputable fiberglass pool manufacturers in North America. The websites and videos we link to are not brand preferences. They were selected based on the quality of the information and visuals. This article is meant to be brand-neutral.

Covered in this article:

- Overview

- What is fiberglass?

- Fiberglass pool pros and cons

- Pros

- Cons

- Flexion

- Sharp Impacts

- Fiberglass pool chemistry

- Traditional range chemistry (almost)

- Fiberglass chalking

- How to fix oxidized fiberglass (chalking)

- Proactive, LSI-focused chemistry

- How to maintain a fiberglass pool year-round

- In-season

- Out-of-season and winterization

- How to maintain a fiberglass pool year-round

- Traditional range chemistry (almost)

- Conclusion

Overview

There are three primary types of swimming pools used in the United States:

- in-ground concrete (or gunite) pools, which have cementitious finishes (plaster, quartz, or pebble),

- in-ground (or above-ground) vinyl liner pools, which use a metal or plastic frame that holds a water-tight vinyl membrane to line the inside of the vessel, and

- in-ground fiberglass pools, which are pre-fabricated monolithic fiberglass vessels, protected by a gel coat finish.

This article focuses solely on fiberglass pools. Fiberglass pools are under-represented in pool chemistry conversations, and they are growing in popularity.

Let's begin by defining fiberglass pools as prefabricated fiberglass pools made in factories. These pools are then delivered in one piece to the job site and lowered into the ground using a crane or excavator of some kind.

The fiberglass is generally about 3/8-inch thick (or thicker) and coated with a smooth gel coat finish. This is different from in-ground concrete pools that have been coated with a fiberglass interior during a renovation. Those types of pools exist too, and the same chemistry considerations exist, but structurally they are quite different than true factory-made fiberglass pools.

What is fiberglass?

Fiberglass is a type of plastic material that is reinforced by glass fibers and resins.1 The result is an incredibly strong strength-to-weight ratio, which is why fiberglass is used across many manufacturing industries (think cars, boats, furniture, and more). Fiberglass is waterproof and durable, largely thanks to its outermost layer: the gel coat.

The fiberglass gel coat is an epoxy resin applied to fiberglass material to give it a smooth, glass-like finish. While durable, it is not invincible. Over time, gel coats can deteriorate, as we will discuss in the chemistry section of this article.

Fiberglass pool pros and cons

Pros

Fiberglass pools are pre-fabricated in factories, where conditions are ideal for material strength and consistency. Quality control in a factory is usually superior and more consistent than construction done in the field. The fact that fiberglass pools are monolithic (meaning they are made in one piece) is a major advantage. Provided the hole in the ground and plumbing are installed correctly, there are fewer variables to manage on a fiberglass pool installation.

There are also a wide array of color options for fiberglass because gel coats can be just about any color imaginable. We have seen some fiberglass pools that are absolutely beautiful, and until you get right up close to them, you cannot even tell they are fiberglass. They often look like concrete pools with high-end finishes in them.

Fewer project variables translate into faster installation compared to in-ground concrete pools. From what we have seen over the years, this means fiberglass pools can be less expensive than concrete pools. This is not certain for every pool, of course, because we have seen some elaborate fiberglass pools with intricate decking and outdoor features. Conversely, we have seen many bare-bones concrete pools too. But in general, lowering a one-piece fiberglass pool with a crane is going to be a simpler project than an in-ground concrete pool.

Another advantage is the smooth finish, which is not going to be subject to issues like calcite crystals or calcium nodules.2 That being said, the finish can become rough because it is not immune from prolonged aggressive water or issues like calcium sulfate scale crystals.

Cons

In terms of cost, fiberglass pools are usually between concrete and vinyl liner pools. But the options for fiberglass pools are more limited. Design options are limited because a fiberglass pool needs to be made in one single piece, and it needs to be transported to the job site on public roads. So there are some obvious size limitations for fiberglass pools.

There are also hydraulic limitations because most fiberglass pools do not have main drains or floor returns. Usually, all plumbing in and out of the pool is on the walls. This is not necessarily a big deal during normal operation, assuming the pool has a low intake to circulate water from the bottom of the pool...but that's something the manufacturer and installer need to decide to do. If you are considering a fiberglass pool, be sure the company has low suction intakes with VGB-compliant drain covers for optimal circulation.

Now let's look at two structural considerations and the water chemistry of fiberglass pools.

Flexion

If improper backfill materials are used (like sand), groundwater can percolate in and shift the foundation behind (and beneath) the fiberglass pool. This can lead to settling around the pool. A pool full of water is very heavy, and if the ground beneath it settles or shifts, the plumbing pipes will likely move with it. Plumbing connection failures are one of the main causes of leaks in fiberglass pools. It can be prevented via proper installation and backfilling practices.

To expand on that, let's introduce a concept called flexion.

Visualize ground pressure from outside of the fiberglass pool, pushing inward on the pool. This pressure can force the fiberglass shell to bend, and that flexion will move other parts of the shell to compensate. Since it's one monolithic fiberglass shell, significant-enough pressure from any angle can move the entire shell. In a simplified and exaggerated analogy, think about twisting and bending a plastic ice tray to release ice cubes made overnight in the freezer. That's the same basic idea.

This video from River Pools & Spas explains flexion issues pretty well:

Even if such flexion does not break the fiberglass itself, spider cracking in the gel coat is a common symptom that weakens the finish enough to lead to more problems in the future. Bottom line: flexion is a problem we do NOT want to encounter in a fiberglass pool, so hire a reputable company to install the pool correctly the first time.

Sharp impacts

The other structural weakness of fiberglass pools is that they do not hold up well against sharp impacts. Sure, this isn't very common, but imagine a heavy piece of pool furniture being thrown into the pool from a hurricane or from vandalism. If an object is heavy and rigid enough, it can crack–and even puncture–a fiberglass pool. One case we heard of was a heavy grill that somehow fell into the pool and smashed into the sun shelf. The pool was ruined.

But it doesn't have to be something so dramatic as a heavy grill. And it doesn't even need to be a puncture to cause a problem. Fiberglass can be scratched pretty easily. Think of metal feet on lounge chairs that might be on a sun shelf or rocks that get into the pool. These can easily scrape fiberglass finishes and leave permanent scars, just like scratching the paint off a car.

Fiberglass pool chemistry

Traditional range chemistry (almost)

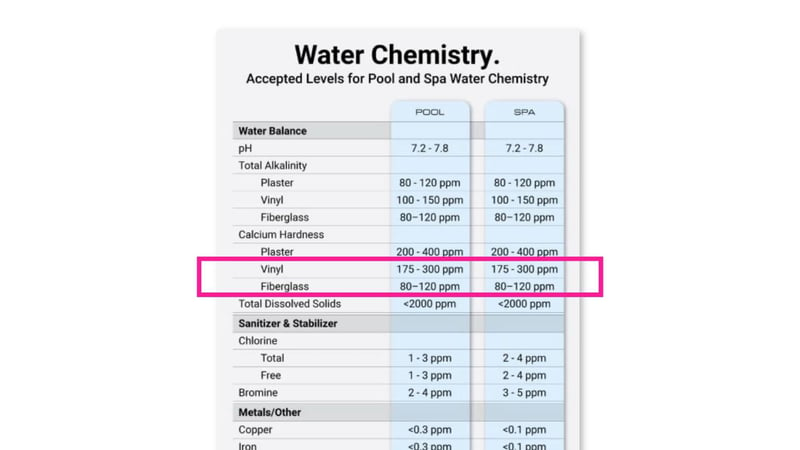

While manufacturers might differ slightly in their water chemistry recommendations, most include some form of traditional pool industry range chemistry parameters. And just like vinyl liner pools, fiberglass pools often have different recommended chemistry parameters than in-ground concrete pools.

But why? To us, water is water...regardless of the vessel that holds it. We at Orenda prioritize the water's need for balance, which is why we focus on the LSI first, and range chemistry second. In our opinion and experience, chemistry ranges should be considered within the context of the LSI.

The one parameter that surprises us the most is when fiberglass pool owners are instructed to keep calcium hardness below 200 ppm. The argument we hear most often is that because fiberglass and vinyl pools don't have readily available calcium, calcium hardness is less important in such pools.3

Water chemistry ranges from a fiberglass pool manufacturer's website.

While there is no doubt that fiberglass is more resilient to low-LSI water than cement or vinyl, remember that water will always seek to return to its natural state of balance. If it cannot get the calcium from the fiberglass (which it cannot), other components of the pool may be negatively affected. And while a low LSI itself is not what causes metal corrosion, the parameters that can cause a low LSI are often contributors to corrosion (like high TDS and low pH).

Low calcium hardness virtually guarantees aggressive water for most of the year. Lab studies are being done by some fiberglass pool manufacturers to observe the long-term affects of this and other chemistry parameters. We are excited to see the results when they come back.

Fiberglass chalking

The main concern is what we have nicknamed "chalking", which is when a fiberglass pool begins to turn white. It starts as a light haze, and can get worse over time. Our original theory was that low-LSI water is degrading the gel coat, and the polymers in the gel coat were being oxidized. As tests have shown, however, this is not what is actually going on. We know the white substance is not calcium carbonate because pure acid on it does not clean it up.

It turns out, through preliminary lab results, the white 'chalking' contains calcium oxide (CaO) that appears to be bound within the gel coat. We do not yet have conclusive evidence of why this is occuring, but it seems to be what is happening. Calcium oxide is not calcium carbonate, and as far as we know, not directly predicted using the LSI either. Read more about the latest information on these tests here:

Related: What is fiberglass "chalking"?

So far, the best theory has to do with the density of the gel coat and its crosslinking with the molecules around it. Notice the edges of the steps in the photo above. The top edge (outside radius) is darker and less "chalked" than the rest of the pools, whereas the base of each stair (inside radius) is much lighter and more "chalked". This leads us to believe the density of the gel coat matters.

The outside radius of the step is more dense because in the manufacturing process, the gelcoat is sprayed onto a mold, which is the inverse of the pool's shape. That means the top outside radius of the step is actually the inside radius when the gelcoat and fiberglass are applied. The base of each stair is the outside radius in the factory, so it's going to naturally be less dense.

This visual evidence leads us to believe that calcium oxide (for some unknown reason) is getting into the gel coat itself and binding with something. When we know more, we'll share it.

So if a fiberglass pool is turning white, it's probably chalking, not carbonate scale. One way to tell is to know the water chemistry history and what the LSI has been. Another is to put diluted acid on a rag and wipe the affected areas (wearing safety gloves and glasses, of course). If the white discolorations are actually carbonate scale, they should fizz and bubble as the acid dissolves the calcium carbonate. If nothing happens, it's probably chalking.

How to fix oxidized fiberglass (chalking)

Fixing fiberglass chalking requires removing the layers of oxidized gel coat and reapplying a new gel coat. It involves a multi-day process where the pool needs to be drained, and it can be costly. Here's a good video we found online demonstrating the process:

While an oxidized gel coat on a boat or car can be buffed and waxed, fiberglass pools cannot. This is because fiberglass wax and sealant products are organic and petroleum-based. CV-600 enzymes would devour such products, and chlorine would oxidize them too.

An alternative to applying a new gel coat would be to install an ecofinish, demonstrated here:

Proactive chemistry and SC-1000

We prefer a more proactive approach. We were fortunate enough to be involved in some of these lab studies, and our SC-1000 chelating agent was used. It proved to be highly effective in all circumstances in preventing chalking. We've been told even with 1000 ppm calcium hardness in the sample water, no chalking occurred because all the calcium was chelated.

So while fiberglass is more resilient to aggressive water than other pool surfaces, chelating calcium appears to be a necessity, even with LSI balance or without. This surprised us, but hey, follow the evidence.

How to maintain a fiberglass pool year-round

Remember, there are two disciplines of pool chemistry: water quality and water balance. From a water quality perspective, there are no significant differences between fiberglass and other types of pools. And like any other pool, the focus of water balance is to keep the water LSI balanced year-round.

To maintain LSI balance year-round, we must account for water temperature! If the pool is in a location that experiences different seasons and cold temperatures, water temperature drives our water balance strategy at different times of the year.

In-season

We recommend maintaining the pool just like any other type of pool. For water quality, avoid over-chlorination and algaecides. For water balance, the Orenda Calculator® will show you your options, and you can take Orenda Academy for more information too.

Out-of-season and winterization

Most fiberglass damage occurs during the winter. In fact, most damage to any type of pool occurs during the winter too, because the water is cold and, therefore, the water is more aggressive. Winterization, on the water balance front, is as simple as preparing the water for the cold months ahead. On the water quality front, remove contaminants before closing the pool so it's easier to open in the spring. And be mindful of the type of pool cover used because it impacts the chemistry needed for the winter.

Conclusion

Structurally speaking, fiberglass pools are different than in-ground concrete pools and any type of vinyl liner pools. In many ways, they are lower maintenance and provide great value for the dollars spent. That being said, fiberglass pools are not invincible, so proper installation and maintenance are required.

The single biggest chemistry issue we hear about is chalking, which seems to be the result of calcium oxide penetrating into the gel coat and binding to something within. Lab tests are ongoing and we do not yet have enough information on this. But we do know, so far, that SC-1000 has proven highly effective at preventing the issue, because if all the calcium in your pool is chelated, it will not bind to the gelcoat.

1 One of the best resources for fiberglass information is from Fibreglass Direct website.

2 Calcite crystals and calcium nodules are the result of calcium hydroxide coming out of a cementitious finish, either from being pulled out (crystals) or pushed out (nodules). But neither of these can form in fiberglass pools because there is no calcium in the material. There is an exception to this, and it is worth an explanation. There have been rare cases of calcium nodules forming in fiberglass pools, but these were not pre-fabricated fiberglass pools. These nodules formed in concrete pools that had been renovated with a fiberglass finish on top of the old plaster finish of an in-ground concrete pool.

3 Cement-based finishes are rich in calcium. Vinyl liners also (surprisingly) contain calcium carbonate within them. But fiberglass has no calcium for water to dissolve and correct its own LSI balance. What, then, will water do to balance itself? And what other aspects of the pool (like the equipment) can be affected?